Critical minerals: South Africa is the world's third largest producer of vanadium. Photo © Bushveld Minerals

As South Africa transitions from coal-fired energy to renewable sources such as solar and wind, the success of green energy technologies will depend on the integration of batteries and energy storage solutions.

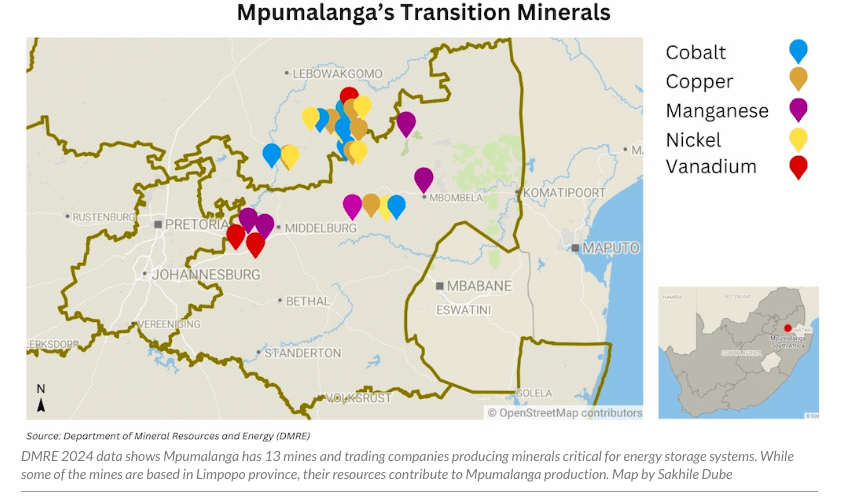

Mpumalanga, an energy hub in transition, is rich in key minerals needed for green energy storage, such as nickel, copper, cobalt, vanadium and manganese, but most of these resources are exported.

There are 13 mines and companies trading transition minerals in Mpumalanga, according to the Department of Mineral Resources and Energy's database for 2024. Some are indirectly involved in renewable energy storage solutions, while others are in maintenance and repair, according to Oxpeckers research.

The Nkomati mine in Machadodorp has significant nickel reserves and is the country's leading nickel producer. Manganese Metals Company (MMC), based in the provincial capital, Mbombela, is a major producer of high-purity electrolyte manganese metal, which is essential for electric vehicle batteries.

South Africa is the world's third largest vanadium producer, with companies such as Bushveld Energy and its Mpumalanga facility playing key roles in vanadium production. Bushveld recently announced plans to sell its main vanadium producer, Vanchem, for up to $40.6 million.

International Market

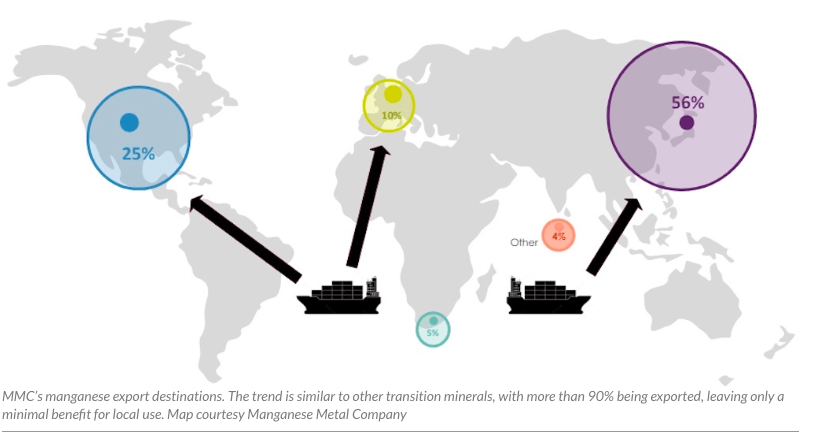

Bushveld Energy chief executive Mikhail Nikomarov said there was huge potential for future development and investment in transition minerals in the state, but local producers were mainly serving international markets, despite growing domestic demand for energy storage systems.

“Most of South Africa's vanadium is exported, mainly for steel, and only around 10 percent is used domestically. Nickel, traditionally used for plating, has more recently been used in batteries and is largely exported,” Nikomarov said.

MMC is a leading international exporter of electrolytic manganese metal for a variety of applications, including lithium-ion batteries. “Around 95 percent of our production supports international markets, such as Europe and North America. As a result, only around 5 percent of our production benefits the domestic market,” said MMC CEO Louis Nel.

Imported kit

Traders who make battery packs and assemble energy storage systems tend to rely on imported kit rather than manufacturing locally. These components are produced by international companies using some of the critical minerals originally exported from Mpumalanga, highlighting major gaps in local manufacturing capacity and supply chains.

Nikomarov noted that the lack of a large domestic market to drive economies of scale makes it difficult for Mpumalanga to compete in the renewable energy storage solutions sector. While it has a competitive advantage in vanadium, manganese and nickel, the province loses that advantage further down the value chain, such as in manufacturing.

“There is a big demand for energy storage solutions but the local supply chain is underdeveloped,” he said.

Nikomarov added that the province needs more large-scale manufacturing facilities. His company is a major contributor to the development of vanadium redox flow batteries for large-scale energy storage and has an electrolyte manufacturing facility in Emalahleni, Mpumalanga, which is home to 12 coal-fired power plants and 142 renewable energy projects, according to #PowerTracker data.

MMC's Nel said providing incentives for local production and investment in renewable energy storage was essential. “The imposition of trade restrictions or tariffs on imports could encourage local production, but this needs to be balanced against potential increases in costs,” he said.

To support domestic manufacturing, Nikomarov suggested government policies should mandate higher local content for certain transitional technologies. “Incentives can be introduced, like those for companies in other countries or industrial development zones,” he said.

Nikomarov suggested that offering other incentives, such as meaningful tax breaks for businesses, could also encourage local production. Current tax breaks that allow private consumers and businesses to reduce their taxable income on the cost of renewable energy generating assets have been increased to 125% from 100%, but “the cap is too low and will not have an impact on businesses,” he said.

Capital Investment

Natasha Ross, senior lecturer at the University of the Western Cape's chemistry department, told Oxpeckers that setting up a manufacturing plant for renewable energy storage production requires significant capital investment.

She gave the example of Bushveld Minerals partnering with the Industrial Development Corporation on a project to build a flow battery electrolyte plant in East London. She said Mpumalanga needed more of these types of investment partnerships.

Ross said determining whether it would be more competitive to manufacture a part locally rather than importing it was a complex and multifaceted task, which would involve assessing factors such as cost efficiency, technological capabilities, supply chain infrastructure and market demand.

“On the one hand, domestic manufacturing has the potential to reduce dependency on imports, create jobs and stimulate the economy. On the other hand, it requires significant investments in technology, skilled labour and infrastructure that may not be readily available or cost-effective,” she said.

More advanced skills

Nikomarov said there was a lack of research and development expertise and advanced skills that could provide solutions to utilize critical minerals for the state's benefit.

Boosting the local economy, creating jobs and improving skills is only possible with the support of relevant stakeholders who can set up manufacturing facilities, he added. “Labour costs may be cheaper than Europe but they are not cheaper than India.”

For Mpumalanga to be competitive as a region, it “needs to look at areas where it has a competitive advantage and focus on specific parts of the supply chain rather than the whole”, he advised.

Nikomarov said cell manufacturing would be feasible with sufficient government support, but producing the cathode active material, lithium salts and separators that are fundamental to lithium-ion battery performance, safety and scalability would be difficult due to the scale and technical expertise needed to succeed.

Gaylor Monmason-Clare, senior economist at independent research organisation Trade and Industry Policy Strategy, told Oxpeckers that securing investment in renewable energy manufacturing requires national and global competitiveness, and investors tend to favour economic centres such as major metropolitan areas or coastal areas close to ports.

“Large-scale manufacturing investment in Mpumalanga requires a very favourable environment, including robust policy support,” Monmasson-Clair said.

Untapped Opportunity

While there are untapped opportunities, building manufacturing facilities locally often takes years, and time is not on transition traders' side amid pressure to close coal-fired power plants in the state in response to tackling the global climate crisis.

Nel noted that the process of extracting and refining critical minerals is highly dependent on electricity.

“Manganese production is energy intensive and becoming increasingly costly due to skyrocketing electricity prices in South Africa,” he said. “The energy-intensive nature of the production process is squeezing profit margins and making it increasingly difficult to remain competitive in the local market.”

Nel said the province could benefit from upstream mineral extraction, beneficiation (removing unwanted minerals to increase the value of the ore), and smelting and refining. A focus on developing raw materials used in the manufacture of active materials for batteries and other components, such as vanadium and nickel processing, where Mpumalanga has a competitive advantage, could strengthen local supply chains.

But all these ambitions will require extensive research and development, he said.

“At the moment there is a lack of substantial research. Ideally, we would like to see universities conduct more research on nickel and its applications, and also on vanadium,” Nikomarov added.

New environmental issues

The expansion of renewable energy storage solutions comes with several new environmental challenges. Mpumalanga province, which produces about 80% of South Africa's coal and is home to Eskom's plants, already faces air and water pollution, biodiversity loss and other impacts from fossil fuel production.

To address new challenges, the Ministry of Environment announced its intention to exempt in 2023 certain activities related to the development and expansion of battery storage facilities from the cumbersome procedures associated with obtaining environmental approvals.

The exemption applies to activities in areas deemed to be of “low or moderate environmental sensitivity,” and critics say it simplifies the implementation process for renewable energy and storage projects, but also raises concerns about non-compliance.

For example, the manganese mineral refining process generates a variety of wastes that may contain residual metals and chemicals. The disposal of these by-products must meet strict environmental regulations, as disposal in landfills can contaminate soil and groundwater with heavy metals and other contaminants. Landfills occupy large areas of land, which can also displace inhabitants and affect biodiversity.

Technical Services

“To address the landfill issue, we have completed engineering work to produce clay bricks and cement fibre from manganese by-products. We have also carried out environmental work such as leaching tests to ensure safety,” Nel said.

The challenge now is commercialization, Nel said. “We need to produce large volumes of bricks for industrial buyers, as well as state and local governments, which are our key customers. Unfortunately, the market for cement fiber is dependent on government support.”

The manufacturing process for vanadium batteries involves handling sulfuric acid and waste materials, which requires strict environmental compliance to prevent pollution and ensure safety.

Nikomarov said it was important for the region to address these environmental and social impacts as it develops its renewable energy production and storage capacity.

The investigation, by Sakir Dube, a freelance journalist focusing on renewable energy and climate change, Oxpecker #PowerTracker Project and the Africa Climate Foundation The heart of the new economyFollow the development of energy projects across Mpumalanga with Oxpeckers #PowerTracker Tool.