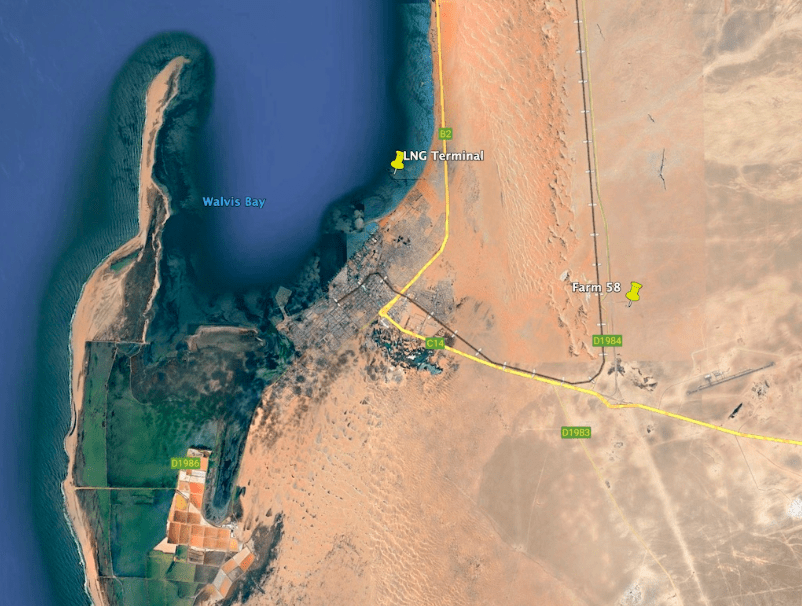

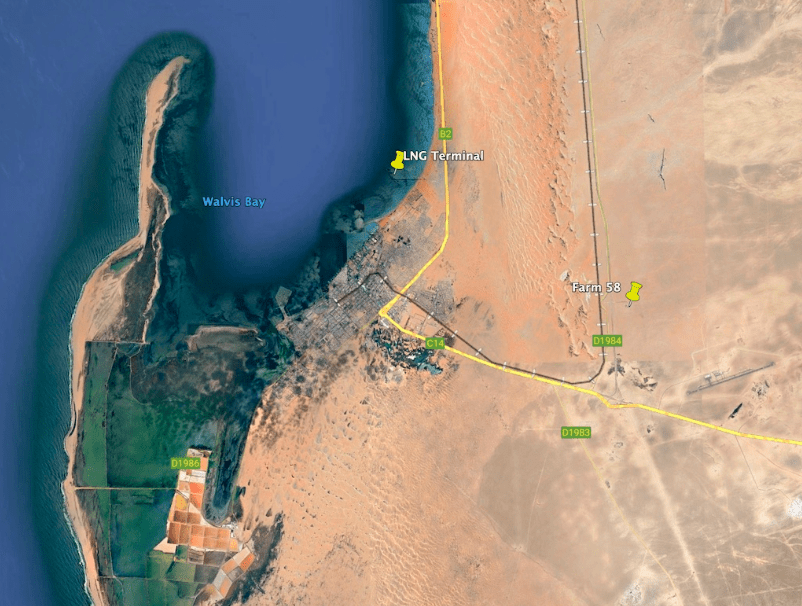

Farm 58 is the first of a three-phase project that will lead to a new industrial area called Northport, in the northern suburb of Walvis Bay. Graphic courtesy

As a strategic location to showcase cutting edge green technology to emerging markets, Cleanergy’s state-of-the-art green hydrogen plant at Farm 58 on the outskirts of Walvis Bay couldn’t be better.

Not only is it the crossroads of roads linking Namibia's three planned northern and southern green hydrogen corridors, but it is also where hundreds of foreign-registered fuel tanker trucks pass every day on their way to and from the port.

On a recent misty Friday morning, most of the trucks that passed Cleanergy's site were foreign-registered, transporting fuel to the mining industries in neighboring landlocked Democratic Republic of Congo, Zambia and Botswana.

So how many fuel tankers will need to pull off the highway and refuel at Cleanergy's two new hydrogen pumps before the $30 million investment in a state-of-the-art hydrogen plant and training center starts to pay off?

“The first step is to bring in an entirely new technology and gain experience, which always takes a long time,” said Satish Ravi, chief field engineer at Cleanergy, especially if it requires upskilling the local workforce to make it sustainable.

Since the late Namibian President Hage Geingob unveiled his ambitious green hydrogen economy vision in June 2021, Cleanergy, a Belgian-Namibian joint venture between CMB.TECH and Orthover & List, has made the most visible but limited progress of nine green hydrogen projects in development, according to independent energy consultant Dettloff von Etzen.

Cleanergy's 5MW solar power plant is already installed and can produce 600 kg of green hydrogen per day under optimal conditions, but if the solar plant is expanded and the electrolyzer is operated at its full design capacity, it can produce up to 900 kg, Ravi explained.

A technological marvel

The Farm 58 plant is an engineering marvel of stainless steel and imported high tech, built to the highest European standards, with each electrical component earthed to a grid buried beneath the plant.

For water, the plant will use about 15 cubic meters of city-supplied water per day, roughly the same amount used by a local fish factory. This equates to 25 liters of water per kilogram of hydrogen produced, most of which will be used to cool and maintain the plant.

While that's not a lot of water for this type of plant, it's still a concern in water-scarce countries and municipalities. With that in mind, the plant is designed to recycle any water not used in the electrolysis process and use it to water the gardens the company is cultivating around its futuristic new training center, due to open in early 2025.

Most of the trainees will be from the Namibia Institute of Mining Technology (NIMT) based at Arandis in the Erongo region and will be trained in skills such as converting diesel trucks into diesel-hydrogen hybrid units.

This involves modifying the intake manifold and fitting a stack of hydrogen tanks that requires the truck's chassis to be extended, a process that will increase the list price of the new truck by around 30 percent, but will also reduce diesel consumption and associated emissions by 30 percent.

When completed, the Farm 58 will be the most modern ship in the world, said Rabie, who previously worked at CMB-TECH's Antwerp-based factory, which is developing hybrid ship engines that run on hydrogen and ammonia for the shipping giant's fleet of 146 ships.

Carbon Emissions

It's unclear whether the project will help reduce carbon dioxide emissions: Many of the trucks that pass through are old, worn-out, smoke-belching models cheaply exported from Europe to Africa.

Eike Kraft, group manager of innovation at Alltuber & List Group and Cleanergy Development Committee member, said that by stacking six hydrogen tanks and making relatively minor modifications to a standard truck's intake manifold and engine management system, some of the worst pollutants could be taken off the roads.

Since 1 kg of hydrogen has the energy equivalent of 3.4 liters of diesel fuel, Kraft explained that Cleanergy's 600 kg of hydrogen fuel per day is enough to refuel 27 dual-fuel trucks. “Once we reach our current production capacity, we can increase our current hydrogen production by either adding more solar power plants or increasing the capacity of our electrolyzers. This technology is [is] “Because it is modular, production capacity can be easily adapted to growing demand,” he added.

There are doubts about whether using green hydrogen and ammonia as fuels is economically viable outside of a few niche applications: since it takes 55 kilowatt-hours of electricity to produce 33 kilowatt-hours of hydrogen fuel, at an estimated cost of $5-9 per kilogram, many argue that it would be more prudent to directly electrify heavy-duty vehicles.

Michael Leibrich, an international authority on clean energy, argues that for this reason, the use of hydrogen in long-distance freight transport is limited to a “small market share” of specialized short-haul trucks used in urban environments. Given the cost and rarity of hydrogen fuel, it seems unlikely that the hundreds of cross-border long-haul trucks that pass Farm 58 every day would be a target market.

“Preparing for the future”

Liesbeth Verhart, local head of CMB.TECH, responded that trucking was just the most visible element of “future-proofing” the Belgian shipping giant's global operations at every stage of the logistics chain. The company's main focus, she said, is on developing and testing maritime applications such as ammonia-fueled marine engines for a new fleet of low-carbon ships currently under construction.

“This is just the first phase and the main aim is to carry out research and development of materials such as steel types and various high-pressure vessels imported from specialist manufacturers,” she said.CMB.Tech also plans to test various applications for powering forklifts, tugboats and other port vessels as part of its efforts to decarbonize its global operations.

The second phase involves acquiring land from Arandis city council to build a 1 gigawatt solar power plant and a hydrogen plant to produce 185,000 tonnes of ammonia per year. The hydrogen produced at Arandis would be sent via a 80-kilometer, high-pressure carbon steel pipeline to the plant at Farm 58 on the coast, Verhart said.

Northport

There, the hydrogen will be converted into ammonia and pumped 10km away to the third phase of the project, a 40,000 tonne ammonia storage and distribution facility to be built in a new industrial area known as Northport, in the northern suburb of Walvis Bay.

The central feature of North Port is the Namibian National Oil Company’s new fuel and gas terminal, designed to house a floating storage and regasification unit to supply mega-vessels designed to transport liquefied natural gas (LNG) in refrigerated tanks.

North Port is central to Namibia's plans for energy independence. North Port and Farm 58 will develop Walvis Bay as a regional energy and mineral beneficiation export hub and form the core of the official Harambee II development plan, which will become known as Walvis Bay Gasport.

On a beach on the outskirts of the still-deserted Northport industrial area, a sign erected in February by Namport and the Port of Antwerp-Bruges during the official visit of Belgium's King Philippe proclaims Walvis Bay the “gateway to Namibia's green industrialization process.”

Phase three is still several years away, but Cleanergy has already secured space for an ammonia storage and distribution plant in Northport, Kraft confirmed.

Oil refinery

An Environmental Impact Assessment Notice on behalf of Ikkaya Somandla Family Trading Enterprises (ISF Trading), posted at the local city planning office, shows plans to build a 300,000 barrels per day oil refinery, a 500MW renewable energy plant, battery energy storage facility, storage tanks and associated offices and warehouses on Portion 46 of the Farm 58 Industrial Zone.

ISF Trading plans to take on the largest parcel of Farm 58, according to environmental impact assessment documents filed, and claims to have major financial backing from Dubai and Brazilian investors for the $83 million project, including a $58 billion credit line from Brazil's Central Bank.

ISF says it will create more than 12,000 jobs during construction and about 3,500 full-time jobs, including 80 civil, electrical and chemical engineers, in a country suffering from a shortage of engineers.

Another green hydrogen project, Chiffon Green Hydrogen, and a company called EloChem, are set to occupy the site next door to Cleanergy, according to a site plan submitted by ISF.

Like some other green hydrogen proposals currently being pursued, the scale of these other projects appears to ignore real limitations in terms of local capacity, technical know-how and capital – two key challenges that Cleanergy has overcome so far, according to the study.

Local economist Roman Grinberg pointed to a third, more compelling reason why Cleanergy's project is more likely to succeed than any other green hydrogen project: Of CMB.TECH's fleet of 106 low-carbon ammonia-burning vessels, the company will likely be the main customer for its own ammonia fuel, the costs of which could one day be offset by carbon credits, making the entire operation, in CMB.TECH's words, “future-proof” in every respect.

John Grobler is an associate based in Namibia. Ox Peckers Investigative Environmental JournalismThis research was supported by the Heinrich Böll Foundation.

Check out more research in Oxpeckers' Green Hydrogen series here.